- Newsletter 162 – April 2014

- Newsletter 161 – January 2014

- Newsletter 160 – October 2013

- Newsletter 159 – July 2013

- Newsletter 158 – April 2013

- Newsletter 157 – January 2013

- Newsletter 156 – October 2012

- Newsletter 155 – July 2012

- Newsletter 154 – April 2012

- Newsletter 153 – January 2012

- Newsletter 152 – October 2011

- Newsletter 151 – July 2011

- Newsletter 150 – April 2011

- Newsletter 149 – January 2011

- Newsletter 148 – October 2010

- Newsletter 147 – July 2010

- Newsletter 146 – April 2010

- Newsletter 145 – January 2010

- Newsletter 144 – October 2009

- Newsletter 143 – July 2009

- Newsletter 142 – April 2009

- Newsletter 141 – January 2009

- Newsletter 140 – October 2008

- Newsletter 139 – July 2008

- Newsletter 138 – April 2008

- Newsletter 137 – January 2008

- Newsletter 136 – October 2007

- Newsletter 135 – July 2007

- Newsletter 134 – April 2007

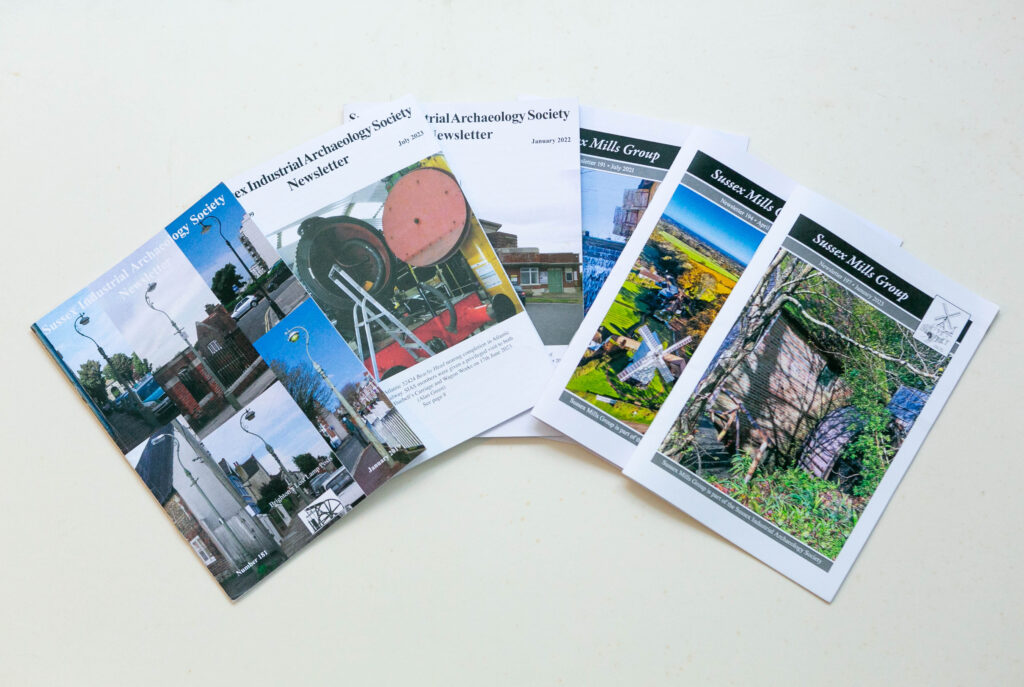

The newsletters below are scanned from printed versions.

Originals of 42 to 133 were in A5 format.Some Issues are not easy to read.

- Newsletter 133

- Newsletter 132

- Newsletter 131

- Newsletter 130

- Newsletter 129

- Newsletter 128

- Newsletter 127

- Newsletter 126

- Newsletter 125

- Newsletter 124

- Newsletter 123

- Newsletter 122

- Newsletter 121

- Newsletter 120

- Newsletter 119

- Newsletter 118

- Newsletter 117

- Newsletter 116

- Newsletter 115

- Newsletter 114

- Newsletter 113

- Newsletter 112

- Newsletter 111

- Newsletter 110

- Newsletter 109

- Newsletter 108

- Newsletter 107

- Newsletter 106

- Newsletter 105

- Newsletter 104

- Newsletter 103

- Newsletter 102

- Newsletter 101

- Newsletter 100

- Newsletter 99

- Newsletter 98

- Newsletter 97

- Newsletter 96

- Newsletter 95

- Newsletter 94

- Newsletter 93

- Newsletter 92

- Newsletter 91

Mysterious structure – conclusion, Lost Mills of Sussex – Sutton, The Hundred of Manhood & Selsey Tramway - Newsletter 90

Jottings from Coultershaw, South Downs Chalk Pits in 1858, Early Wheat Varieties

Sussex Industrial

Sussex Industrial